Tree of Reflections

London, UK

Foster + Partners

Image Source: Brady Peters / Foster + Partners

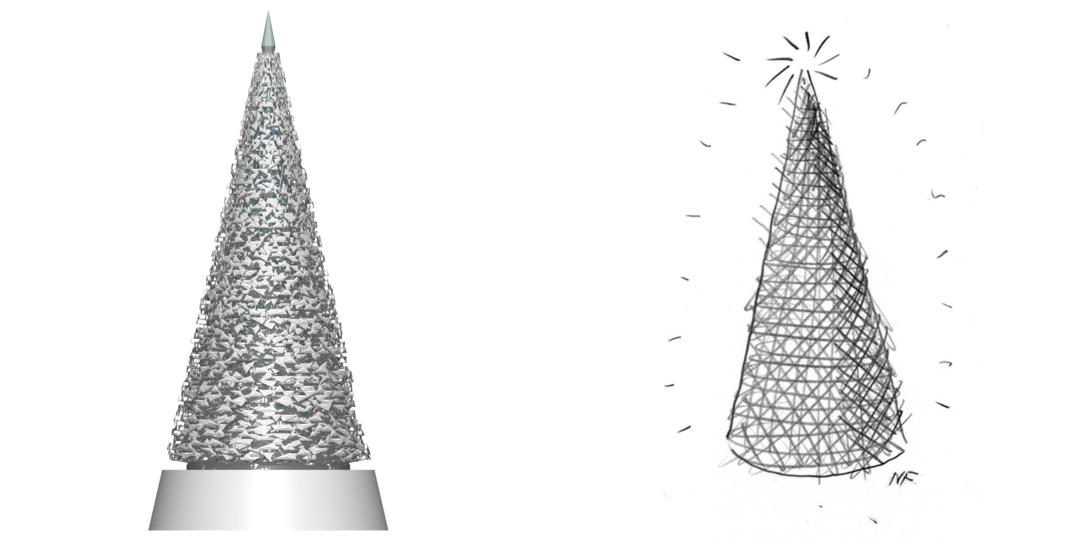

In the fall of 2006, Foster + Partners participated in the Festival of Trees, an annual charity event put on by Save the Children. The Specialist Modeling Group (SMG) was key part of the project team and chose to use this project as an opportunity to research the manufacturing capabilities of rapid prototyping technologies. The overall form of the Foster + Partners tree, called the Tree of Reflections, was that of a cone, the ideal form for a Christmas tree.

Image Source: Brady Peters

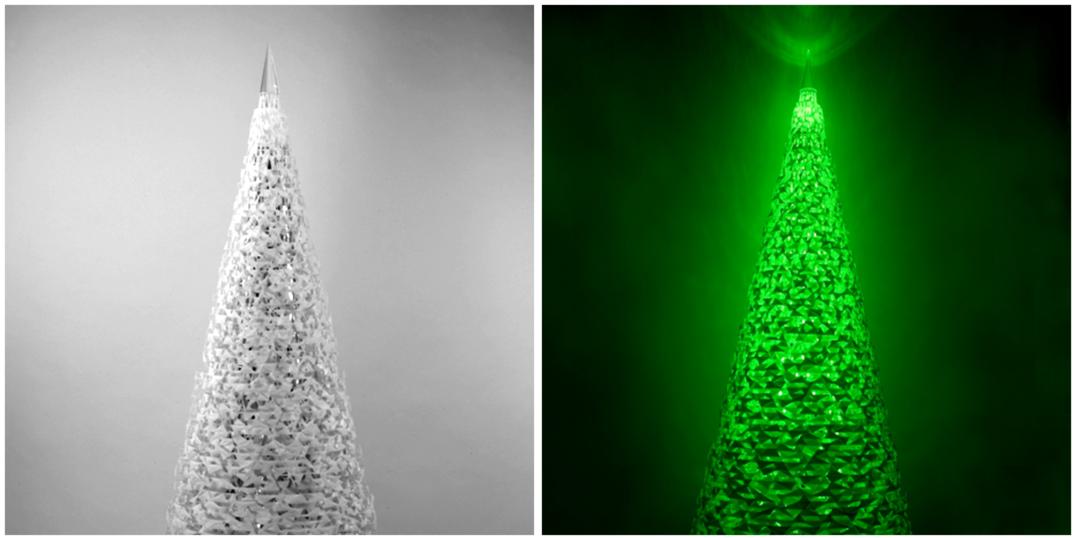

Through the design and fabrication of the Tree of Reflections project we have had a first feel of what it could be like to design and direct layer manufacture the final product. A new set of construction and fabrication parameters have to be taken into account. The known solution space that is dictated by current fabrication, construction and assembly technology is no longer valid. Through rapid prototyping technology, architects can start to experiment with rapid manufacturing, this might eventually shift not only fundamentally the way we construct buildings but also the way we design them. Through rapid prototyping a larger not yet explored application of layered manufacturing in architecture can be researched.

Image Source: Brady Peters

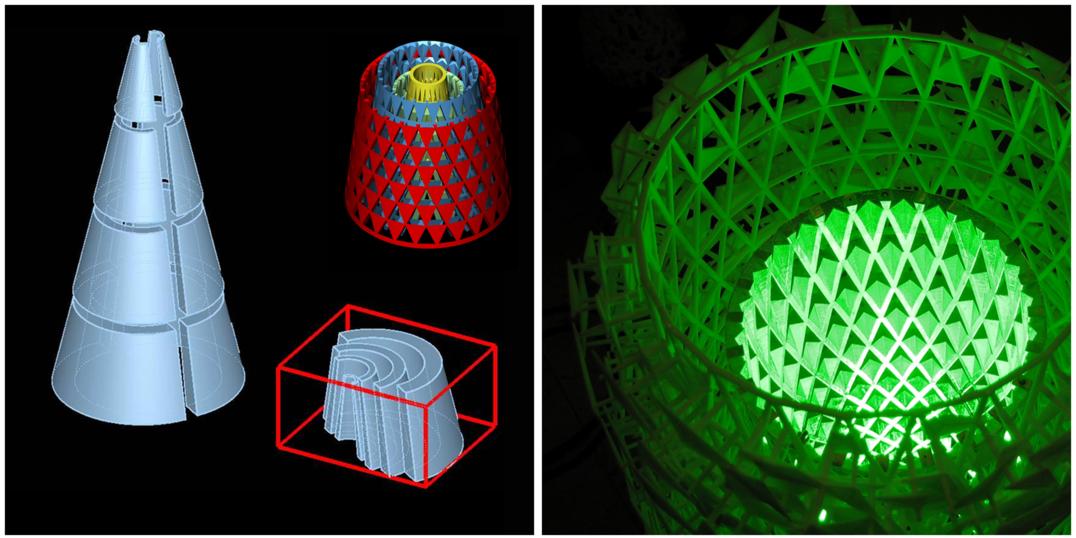

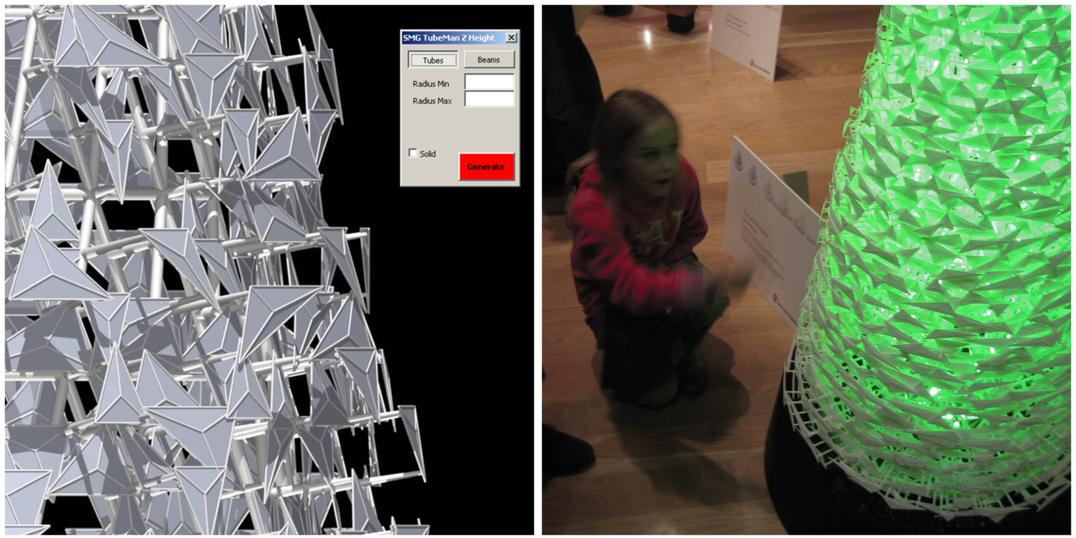

The leaf geometry was generated by a custom computer program. This generative script allowed parameters to be easily changed to suit different manufacturing conditions. The tree was illuminated from within by a high-power LED light. This reflected out through a reflecting cone. The reflecting cone was manufactured with the assistance of Dr. Rupert Soar at Loughborough University, and was then electroplated in silver by Morganic Metal. This reflecting cone sat underneath the leaves and leaf structure, which were manufactured by EOS systems in Germany using the SLS process. As the tree was nearly two metres in height it was necessary to manufacture it in components. It was also crucial that these components could be efficiently nested within the rapid prototyping machine’s build chamber.

Image Source: Foster + Partners